Ikea Striberg Delay Timer

My wife wanted some light inside our wardrobe. Understandable, because when you stand in front of a wardrobe you’re blocking the light coming from behind you. So we bought ourselves an Ikea Striberg LED strip. It has a nice design and is easy to mount. It also features a sensor, which switches the light off whenever you close the doors of the wardrobe. At least that is the idea behind the sensor.

Such a ready made device is not worthy of a project, you might think.

However, it uses a proximity sensor to see whether the doors are open or closed.

Whenever it sees something in front of the sensor (usually a door), it switches the light off.

Therefore you must hang the strip high enough to enable the sensor to look over the person standing in front of it.

Otherwise it will switch off the light when you step too close.

In our case however we don’t want the light to illuminate only the top shelf.

We want it to illuminate the space below that.

So we had to hang the LED strip underneath the top shelf.

This caused the light to be very nervous.

It kept switching on and off at the slightest movement.

A small opaque sticker is supplied to limit the sensitivity of the sensor by covering part of it, but I couldn't get that to work reliably either.

Adding A Delay Timer

So now I can make a project out of it.

I’m going to add a timer circuit, which keeps the light on for at least 30 seconds after it has detected that the doors are closed again, or when someone is standing in front of the sensor.

This means that the light will remain on for another 30 seconds after the doors have been closed, but I don’t mind that.

As long as it doesn’t switch off all the time when we stand in front of the open wardrobe.

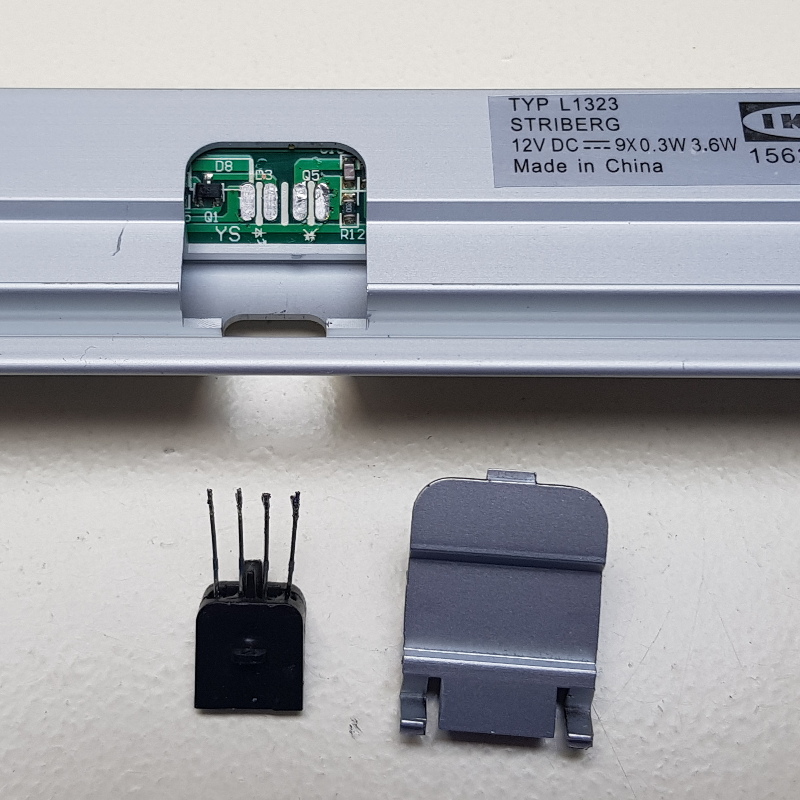

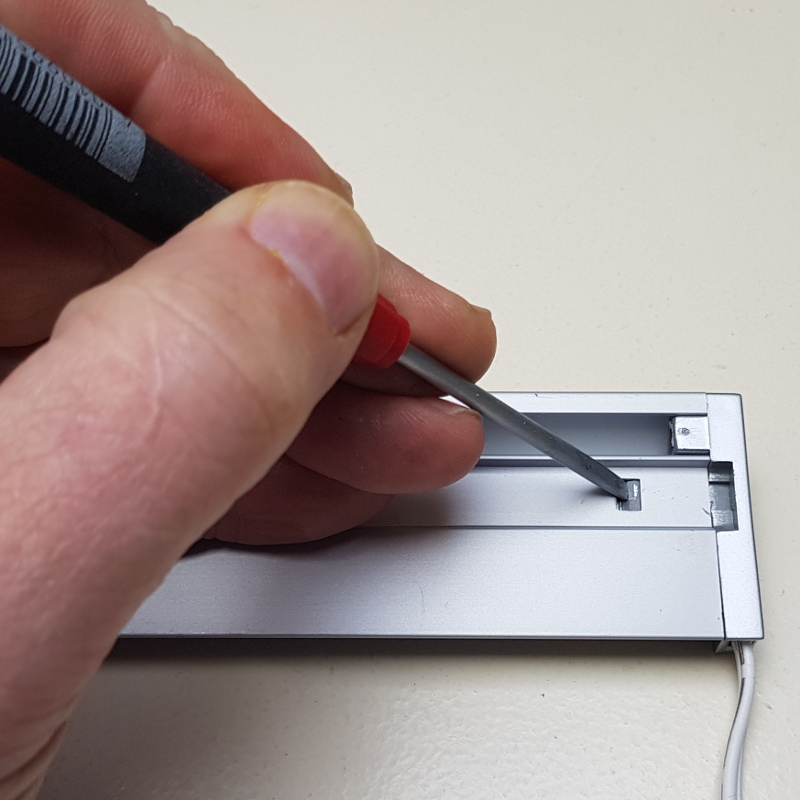

Opening The LED Strip

In order to open the LED strip you’ll have to desolder the sensor first. You can reach the sensor by removing the piece of plastic in the middle of the strip. The sensor is soldered to the PCB with 4 wires. After carefully desoldering these 4 wires you can take the sensor out completely. Then you’ll have to take the two plastic end caps off. Start with the cap with the wire running through. Carefully give the wire some more slack. Then remove the other side, while pushing the PCB in the direction of that cap, otherwise you might damage the switch, which is located on that side. Once that second cap is removed you can pull the PCB out of the aluminium strip from the wired side.

The LEDs are mounted on a long and narrow piece of PCB. The reverse side of the PCB holds the power supply and control logic. All surface mounted parts of course, because it all has to be very low to make it fit into the shallow aluminium strip.

How To Add A Delay Timer?

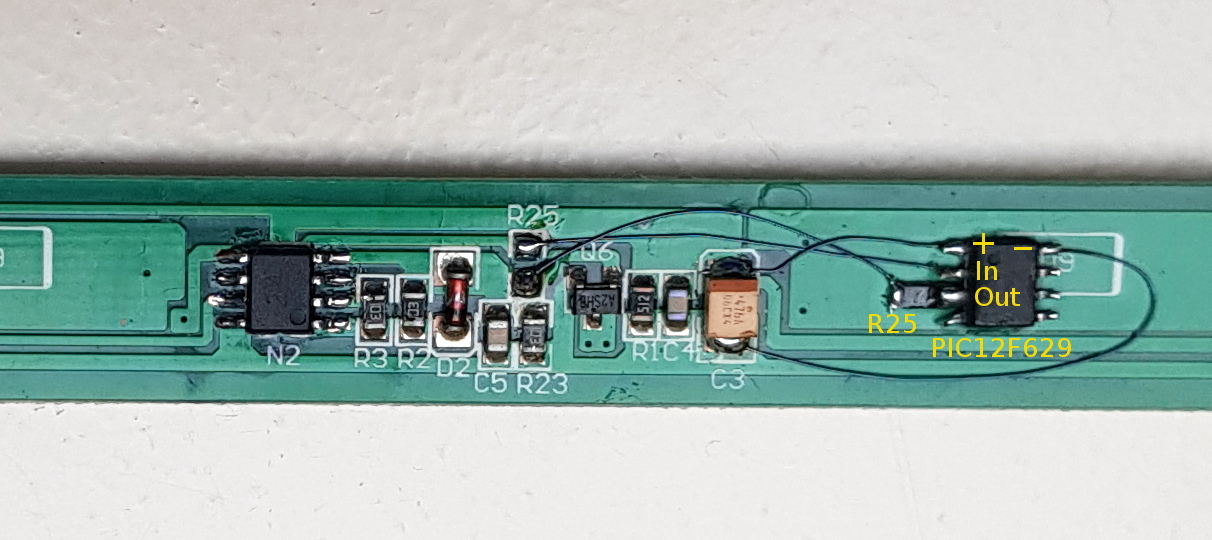

At first I have tried to reverse engineer the software inside the microcontroller (N2) on the strip. Judging by the location of the supply inputs it could have been a PIC microcontroller. So I desoldered it and tried to read the software from it. I don’t know whether the device was read protected, or what else was wrong, but I couldn’t get any data from it. It might not even be a PIC microcontroller. So I had to go for an external timing circuit.

A simple NE555 timer is out of the question, basically because of the number of passive components that have to be added to make it work.

The available space is simply too limited.

I did have some PIC12F629 chips lying around, doing nothing.

PICs are not my favourite processors.

However making a simple timer out of one wouldn’t be too difficult a task for those stupid things.

The Program

The listing of the program, written using my SB-Assembler of course, is included as a download.

The output of the existing controller is tapped off from resistor R25 and fed into GPIO 5 of the PIC controller.

GPIO 4 of the PIC controller is used as delayed output, which now will drive the gate of Q6, through R25 again.

Once the opening of the wardrobe door has been detected the output of the original controller goes high.

The 30 seconds timer gets reset constantly while this signal remains high.

Once this signal goes low the 30 seconds timer gets the chance to count down to 0.

Once it reaches 0 the output signal of the PIC controller goes low too.

Should the input to the PIC controller go high again while the counter is still counting down it will be reset to 30 seconds again.

This will keep the light on for as long as the doors are open up to 30 seconds after the doors have been closed.

The Hardware

Thanks to the use of a microcontroller the modifications to the LED strip are reduced to a minimum and can always be undone. R25 is removed, so output pin 3 of N2 can’t reach R25 any more. The new PIC controller is glued to the PCB, using some super glue. Pin 3 from N2 is then connected to pin 2 of the PIC controller. The output, pin 3 of the PIC controller, is connected to R25 again, which in turn will drive the gate of Q6 again. Power to the PIC controller is taken from C3. The positive side goes to pin 1 and the negative side goes to pin 8.

All that remains now is to put everything together again, in reverse order.