Variac

When you’re working on open mains powered devices it is important to use an isolation transformer.

It makes servicing those devices a lot safer and easier.

I’ve explained this on this dedicated page of my isolation transformer.

An extra bonus is when the output voltage of your isolation transformer can be adjusted between 0 and somewhere around the local mains voltage.

Such an isolation transformer is called a Variac.

Don’t confuse a variac with an autotransformer.

They look very similar.

The output voltage of an autotransformer is also adjustable.

However the output is not isolated from the input.

Therefore an autotransformer won’t contribute to your safety.

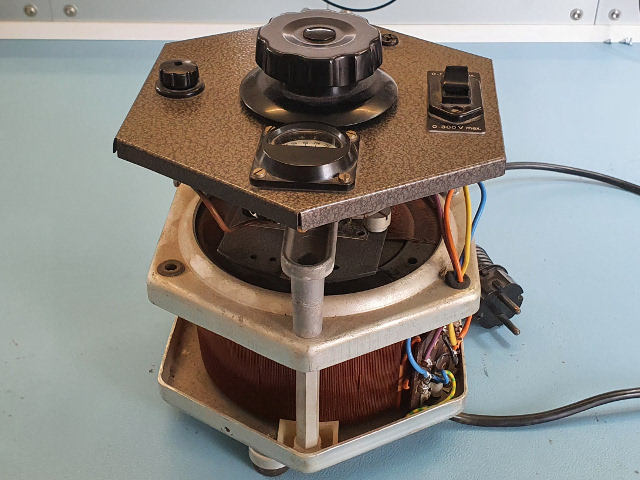

I’ve obtained my variac, together with my PM6668 frequency counter, from an old colleague of mine. I even got some spare carbon brushes, just in case the current one will ever wear out.

Given its origin I expect the Variac was made by Philips. However I can’t find a brand name anywhere on the device. Also the type number B98090002 doesn’t ring any internet bells.

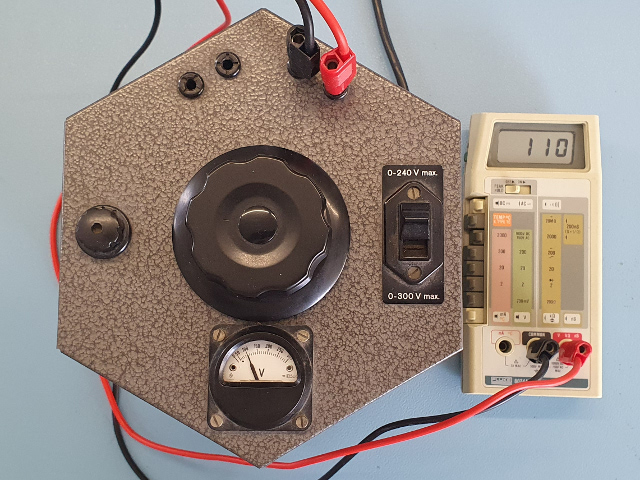

Set to 110V

Set to 110V

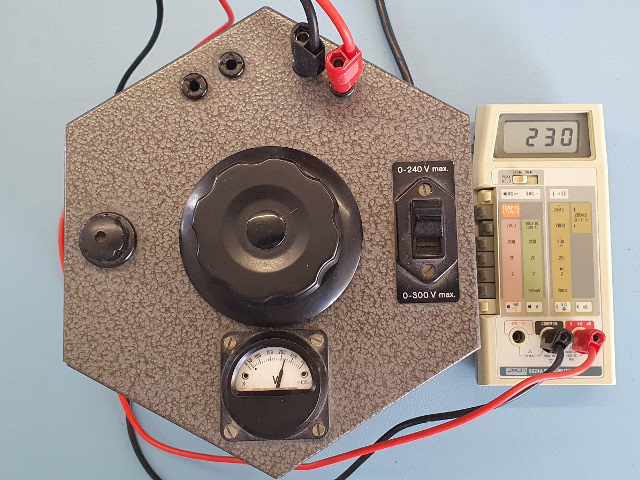

Set to 230V

Set to 230V

The funny thing is that the schematic is printed on the nameplate.

The primary voltage is applied to the transformer taps A and B.

The output is taken from taps E and the wiper tap F.

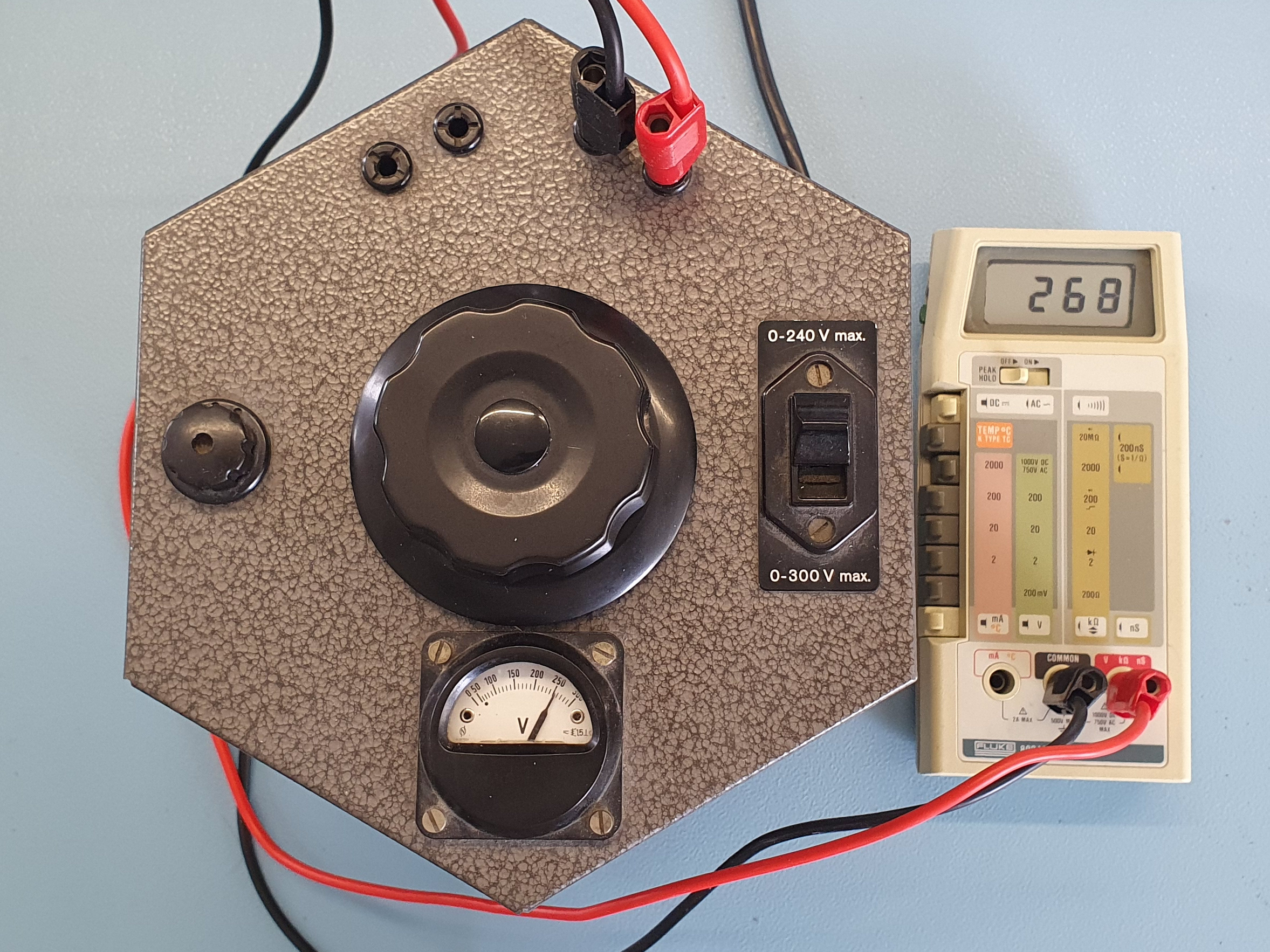

The output voltage can be adjusted between 0V and 265V by rotating the wiper to the required position.

A switch can change transformer's primary tap B to tap C.

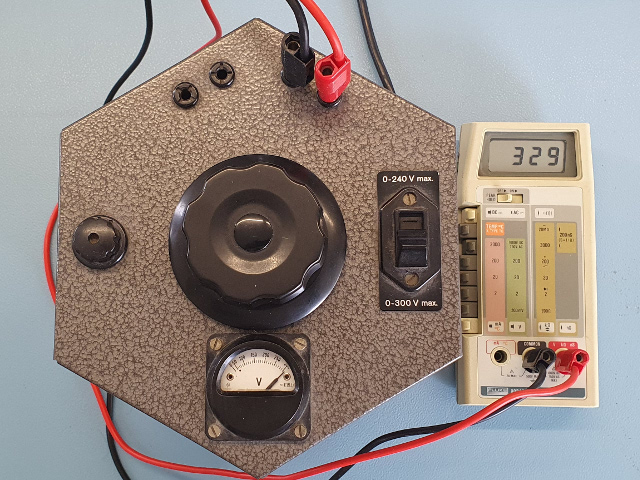

This changes the input to output ratio, which allows the output voltage to be set between 0V and 328V.

No matter what the output voltage is, the maximum output current of this transformer is 1.5A.

Set to full scale low

Set to full scale low

Set to full scale high

Set to full scale high

Some variacs have a voltage scale printed around the rotary knob. Mine doesn’t have one. The output voltage can be read from the little built in Voltmeter. Anyway, I prefer to use a multimeter to check the output voltage, just to be sure I’m not overloading the connected load.

Taking It Appart

Thinking about it, this could well be the only device of mine that I have never taken apart before. It’s about time to change that. The rotary knob was the first to go, easy enough. This exposed three screws, which I immediately removed. There are two more screws on the bottom sides, which I also removed. And then I could lift up the outer shell.

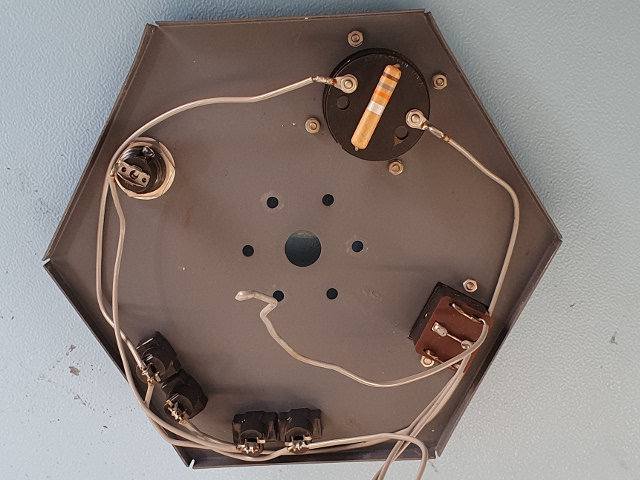

The wires are too short to lift the skirt completely

The wires are too short to lift the skirt completely

However I could only lift it about half way up. The internal wiring prevented me to lift the outer shell completely off. How the hell did they manufacture this thing? I could barely reach in to disconnect these wires. Desperately I decided to cut the wires to replace them later with slightly longer ones. That did the trick, the variac was open.

The wires are still hard to reach

The wires are still hard to reach

This way it's a lot easier

This way it's a lot easier

Once it was open I discovered one more wire, which I haven’t seen before. It originally was connected to the wiper. Reconnecting this wire appears to be impossible.

The wiper

The wiper

Only the skirt removed, life can be so easy

Only the skirt removed, life can be so easy

Then it dawned on me.

The side skirt of the shell was not attached to the top.

All I had to do to open the Variac was to remove the two screws on the opposite sides at the bottom and the skirt could simply slide down, exposing the internals.

Now I only had to restore the wiring to make it all work again, making sure to keep the wires far enough away from the wiper.

Now I know how to open the variac. Important knowledge should I ever have to replace the wiper’s carbon brush.

Use Cases

A variac is a very useful and versatile tool. Here are a few use cases.

- A variac is an isolation transformer. If you don’t have a fixed isolation transformer, use the variac to make tinkering with mains voltages a little safer.

- Running imported 110V devices in a 230V mains area.

- Limiting the maximum speed of my model train. I’ve done this in the past to prevent my train from derailing in the curves when it was driven by young kids. Make sure they don’t discover the variac, for it may allow them to run the train even faster than normal.

- Connect a normal transformer to the output and adjust its primary voltage to get the required low output voltage for your experiments in case you don’t have the required transformer at hand.

- Carefully ramp up the voltage of your device under test in case you don’t know how it will react when it’s powered up immediately.

- Connect a toroid transformer to the output and run a thick cable through the center of the core. This way you create a low voltage which can deliver quite a lot of current. This current can be regulated by changing the primary voltage of the toroid transformer. You may have to run the thick cable through the core multiple times in order to get the voltage/current you want. This way you can easily generate currents of well over 200A. Be careful though not to exceed the maximum power of the toroid transformer or the variac.

- Categorise the power requirements of your device under test. See what the minimum input voltage of your device under test is. And check whether it can sustain its maximum rated input voltage without damage.

- Use it as a paper weight.

With such a long list of applications can you imagine how you have ever managed to live without a variac?